F.I.T. Certified

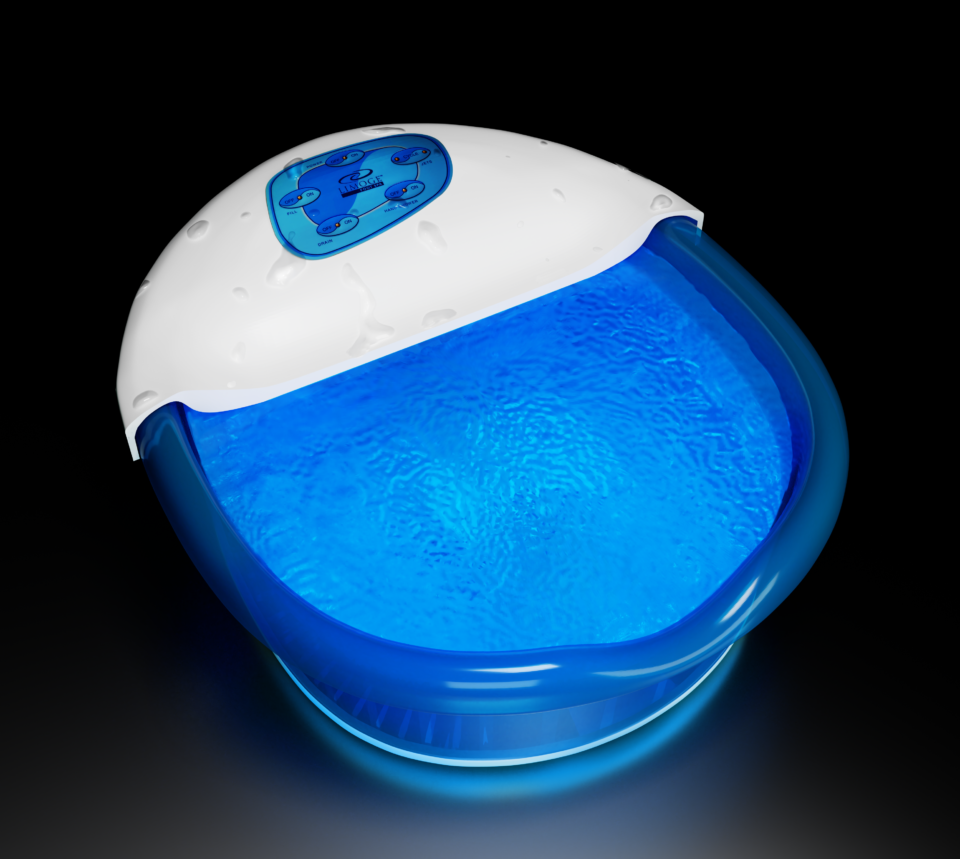

Keypads That Are Designed to Take a Bath

Simply put, all membrane switches are not designed and/or built the same. At SSI, we take pride in understanding and even predicting the potential rigors that our products may eventually need to endure in the field. That, coupled with our many years of experience building product for countless industries arms us with the necessary knowledge.

Top 7 Reasons Membrane Switches Fail

1. Mechanical Failure

Most electrical switches, such as membrane switches and keypads, are designed to move and/or flex. This can mean eventual wear and tear on these moving components. Components can be particularly vulnerable in environments where the operator may be prone to exerting high pressures on the switch and/or if sharp or hard objects are used to actuate the switch.

2. Moisture Ingress

Whether due to outdoor precipitation or liquid cleaning agents, moisture can wreak havoc on electrical switches. Though membrane switches possess some inherent moisture-resistant properties, often additional design and manufacturing safeguards need to be employed to achieve maximum protection against moisture.

3. Humidity

While humidity typically impacts electrical components at a slower pace than liquid, the negative effects can be equally as problematic. In short, it is critical to keep conductive traces and contacts properly insulated from this insidious risk.

4. Temperature Extremes

Differing expansion and contraction rates of the various components used within switches is just one of the risks to consider when designing membrane switches that may be exposed to significant temperature swings. Also, some material can become brittle when exposed to low temperatures, reducing the effective life of these products.

5. UV Rays

Anyone designing a part that will be used outdoors must consider the impact of harmful UV exposure. But, UV rays can also impact product being used indoors via windows. In both cases, proper material selection is paramount to prevent discolorization and eventual weakening of the plastics used in membrane switch technology.

6. Electrocstatic Charges

The static discharge that occurs after a person has built up a significant imbalance of electrical charges in their body can have a profound impact on electronics. A membrane switch is often the first line of defense for such charges and thus neds to provide the proper safeguards to protect itself as well as the electronics for which in interfaces.

7. Chemical

Never has a cleaning and/or disinfecting of shared surfaces been more scrutinized. Membrane switches allow for a surface that can be wiped down easily, but can they withstand the harsh compounds of the cleaning agent? Well, that depends on what materials are chosen to meet the necessary cleaning protocols of the end-use environment.

How Does It Work?

Not only is the process of getting your product certified easy, it’s free. Simply provide us with a blueprint and/or a physical part and we will do the rest. We will assess what sort of failure risks your part needs to mitigate and propose a design and proposal, which ensures that your product will last. The initial assessment is free and better yet, we will stand by every product we manufacture for you.